The Versatile Characteristics Of Nylon Plastic: A Comprehensive Overview

Welcome to our comprehensive overview of the versatile characteristics of nylon plastic. Nylon is a widely used material in various industries due to its unique properties and performance abilities. In this article, we will explore the diverse applications and benefits of nylon plastic, shedding light on its durability, flexibility, and resistance to wear and tear. Whether you are a consumer, engineer, or designer, this article will provide valuable insights into the endless possibilities of nylon plastic. Join us as we delve into the world of nylon and discover its wide-ranging capabilities.

Introduction to Nylon Plastic: A Brief History and Overview

Nylon plastic is a versatile and widely used material in the manufacturing industry. With its exceptional strength, durability, and versatility, nylon has become a staple in a variety of applications, ranging from textiles to automotive parts. In this article, we will explore the history and overview of nylon plastic, as well as its unique characteristics and applications.

History of Nylon Plastic

Nylon plastic was first introduced by the DuPont company in the 1930s. It was the first synthetic fiber to be commercially produced and quickly gained popularity for its strength and versatility. Originally developed as a substitute for silk in the production of stockings, nylon soon found its way into a wide range of products, including ropes, fabrics, and even toothbrush bristles.

Overview of Nylon Plastic

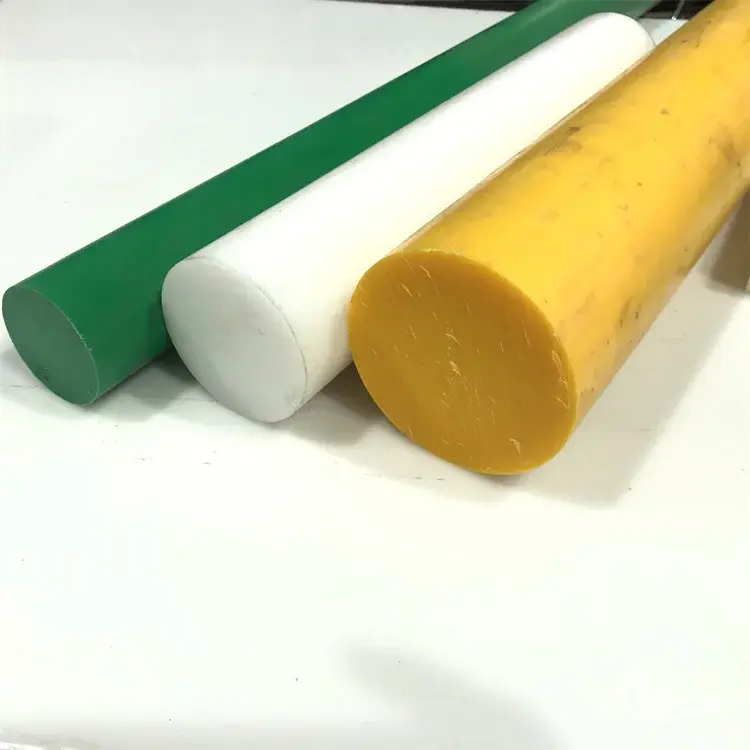

Nylon plastic is a thermoplastic material that is known for its exceptional strength and durability. It is a synthetic polymer that can be molded into a variety of shapes and forms, making it ideal for a wide range of applications. Nylon plastic is also resistant to abrasion, chemicals, and moisture, making it suitable for use in harsh environments.

Characteristics of Nylon Plastic

One of the key characteristics of nylon plastic is its high tensile strength, which makes it ideal for use in applications where strength and durability are essential. Nylon plastic also has excellent resistance to abrasion, making it suitable for use in products such as gears, bearings, and conveyor belts. Additionally, nylon plastic is lightweight and has a low coefficient of friction, making it ideal for use in applications where weight and friction need to be minimized.

Applications of Nylon Plastic

Nylon plastic is used in a wide range of applications across various industries. In the automotive industry, nylon plastic is commonly used in the production of engine components, such as gears and pulleys, as well as in the manufacturing of exterior body parts. In the textile industry, nylon plastic is used to produce strong and durable fabrics, such as nylon taffeta and nylon ripstop. Additionally, nylon plastic is also used in the production of consumer goods, such as toothbrushes, combs, and kitchen utensils.

In conclusion, nylon plastic is a versatile and widely used material with a rich history and a wide range of applications. Its exceptional strength, durability, and versatility have made it a staple in the manufacturing industry, and it continues to be used in a variety of products and applications. As technology continues to advance, the use of nylon plastic is likely to expand even further, making it an essential material for the future.

The Diverse Applications of Nylon Plastic in Various Industries

Nylon plastic is a versatile material that has found its way into a wide range of industries due to its unique and valuable characteristics. From automotive to fashion, from consumer goods to medical devices, nylon plastic has become an essential component in the manufacturing process of many products. This comprehensive overview will delve into the diverse applications of nylon plastic in various industries, shedding light on its versatile characteristics and the benefits it offers to each sector.

In the automotive industry, nylon plastic is widely used for its high strength, durability, and resistance to heat and chemicals. It is commonly found in engine components, such as intake manifolds, valve covers, and oil pans, where its ability to withstand high temperatures and harsh conditions is crucial. Additionally, nylon plastic is used in the production of various interior and exterior parts, such as door handles, seat belt components, and bumper brackets, where its lightweight and impact-resistant properties make it an ideal material.

The aerospace industry also benefits from the use of nylon plastic, as it provides lightweight alternatives for metal parts, reducing the overall weight of aircraft and improving fuel efficiency. Nylon plastic's ability to withstand extreme conditions, such as high altitude and pressure differentials, makes it a valuable material for the production of aircraft components, including engine parts, interior panels, and even 3D-printed aircraft components.

In the fashion industry, nylon plastic is widely used for its flexibility, durability, and ability to be molded into various shapes and designs. From clothing and accessories to footwear and handbags, nylon plastic has become a popular material due to its lightweight nature and resistance to wear and tear. It is often used in the production of waterproof and weather-resistant outerwear, as well as in the creation of durable and stylish accessories.

The consumer goods industry also relies heavily on the use of nylon plastic for the manufacturing of a wide range of products, including kitchenware, electronics, and sporting goods. Its ability to be molded into intricate designs, as well as its resistance to heat and chemicals, makes nylon plastic an ideal material for the production of items such as kitchen utensils, electronic casings, and sports equipment.

In the medical industry, nylon plastic is used in the production of various medical devices and equipment, including surgical tools, implantable devices, and prosthetics. Its biocompatibility, sterilizability, and ability to be molded into complex shapes make it a valuable material for medical applications, where precision and reliability are crucial.

In conclusion, the diverse applications of nylon plastic in various industries highlight its versatility and valuable characteristics. From automotive to fashion, from consumer goods to medical devices, nylon plastic has become an essential material that continues to drive innovation and advancement in manufacturing processes. Its ability to offer lightweight, durable, and chemically resistant solutions makes it a highly sought-after material in today's industries.

The Unique Properties of Nylon Plastic: Strength, Durability, and Flexibility

Nylon plastic is a versatile and widely used material with a unique set of properties that make it an excellent choice for a wide range of applications. From clothing and industrial materials to automotive parts and consumer goods, nylon plastic's strength, durability, and flexibility make it a highly sought-after material in various industries.

One of the most notable properties of nylon plastic is its strength. Nylon has a high tensile strength, which means it can withstand a great amount of tension without breaking or deforming. This makes it an ideal material for applications that require a strong and durable material, such as in the production of ropes, cables, and other heavy-duty industrial products. Additionally, its strength also makes it an excellent choice for structural applications in industries such as construction and aerospace.

In addition to its strength, nylon plastic is also known for its exceptional durability. Nylon is highly resistant to wear and tear, making it a long-lasting and reliable material for use in various applications. Its resistance to abrasion and impact makes it an ideal choice for applications that require a material that can withstand high levels of stress and friction, such as in the production of gears, bearings, and other machinery components. Its durability also makes it a popular choice for outdoor and sporting goods, as it can withstand the harsh conditions of outdoor environments.

Furthermore, nylon plastic is prized for its flexibility. Nylon is a highly flexible and elastic material, which allows it to be easily molded and shaped into various forms and configurations. This flexibility makes it an ideal material for injection molding and other manufacturing processes, allowing for the production of complex and intricate parts with ease. In addition, its flexibility also allows for the creation of lightweight and comfortable products, such as clothing and footwear, where flexibility and comfort are essential.

Another notable characteristic of nylon plastic is its resistance to chemicals and solvents. Nylon is highly resistant to many common chemicals and solvents, making it an ideal choice for applications that require a material that can withstand exposure to harsh substances. This resistance to chemicals also makes it a popular choice for the production of automotive parts, such as fuel lines and engine components, where exposure to various fluids is common.

In conclusion, the unique properties of nylon plastic, including its strength, durability, flexibility, and resistance to chemicals, make it a highly versatile and sought-after material in various industries. From industrial applications to consumer goods, nylon plastic offers a wide range of benefits that make it an excellent choice for a multitude of applications. Its exceptional properties and versatility make it an indispensable material in the modern world.

Advantages and Limitations of Nylon Plastic in Manufacturing and Engineering

Nylon plastic is a versatile material with numerous applications in manufacturing and engineering. This article provides a comprehensive overview of the advantages and limitations of using nylon plastic in various industries.

One of the key advantages of nylon plastic is its high strength and durability. It is known for its excellent mechanical properties, including high tensile strength, resistance to abrasion, and impact resistance. This makes nylon plastic an ideal material for manufacturing components and parts that are subjected to high stress and wear, such as gears, bearings, and pulleys. Its ability to withstand heavy loads and harsh conditions makes it a popular choice in engineering applications.

Additionally, nylon plastic is lightweight and has a low coefficient of friction, making it suitable for applications where weight and friction are important factors. This makes it an attractive option for industries such as automotive and aerospace, where lightweight materials are desired to improve fuel efficiency and reduce overall weight. The low friction properties of nylon also make it an ideal material for use in sliding and moving components, where smooth operation is essential.

In terms of versatility, nylon plastic can be easily molded and shaped into complex geometries, allowing for the production of intricate parts with tight tolerances. This makes it a cost-effective solution for manufacturing custom components in small and large quantities. Its ability to be molded into various shapes and sizes also makes it a favorite choice for 3D printing applications, where rapid prototyping and custom part production are essential.

Furthermore, nylon plastic is resistant to chemicals, oils, and solvents, making it suitable for applications where exposure to these substances is common. This chemical resistance makes it a preferred material for use in the production of chemical processing equipment, seals, and gaskets.

Despite its many advantages, nylon plastic does have limitations that should be considered. It has a relatively high moisture absorption rate, which can lead to dimensional changes and reduced mechanical properties in humid environments. This makes it less suitable for applications where moisture resistance is critical, such as outdoor or underwater applications.

In conclusion, nylon plastic is a versatile and reliable material with a wide range of applications in manufacturing and engineering. Its high strength, durability, lightweight nature, and chemical resistance make it a favored choice for industries requiring reliable and cost-effective solutions. However, its susceptibility to moisture absorption should be taken into account when considering its use in specific applications. Overall, the advantages of nylon plastic outweigh its limitations, making it a valuable material for a variety of industrial applications.

Future Trends and Innovations in the Use of Nylon Plastic for Sustainable Development

Nylon plastic has been a versatile material with a wide range of applications, and with the growing emphasis on sustainable development, its use is expected to undergo significant changes and innovations in the future. This article provides a comprehensive overview of the versatile characteristics of nylon plastic and discusses future trends and innovations in its use for sustainable development.

One of the key characteristics of nylon plastic is its durability and strength, making it a popular choice for a variety of applications. From clothing and automotive parts to medical equipment and industrial components, nylon plastic offers a unique combination of properties that make it suitable for diverse uses. Its high tensile strength and resistance to abrasion and chemicals have made it an essential material in many industries.

Furthermore, the flexibility and moldability of nylon plastic make it an ideal candidate for 3D printing, a rapidly growing technology with the potential to revolutionize manufacturing processes. With advancements in 3D printing technology, the use of nylon plastic in additive manufacturing is expected to expand, allowing for the production of complex and customized parts with minimal material waste. This trend towards additive manufacturing represents a significant innovation in the use of nylon plastic, enabling more sustainable and efficient production methods.

In addition to its physical properties, the recyclability of nylon plastic has also become a focus of innovation for sustainable development. As the world seeks to reduce the environmental impact of plastic waste, efforts to recycle nylon have increased. New recycling technologies and processes are being developed to reclaim and repurpose used nylon materials, reducing the demand for new production and minimizing the amount of plastic ending up in landfills or oceans.

Moreover, the integration of bio-based and biodegradable alternatives to traditional nylon plastic is a promising trend for the future. By incorporating renewable resources into the production of nylon, the environmental footprint of this material can be significantly reduced. Innovations in bio-based nylon production have shown potential for achieving similar performance characteristics while minimizing the reliance on finite fossil fuel-based resources.

Furthermore, the development of sustainable supply chains for nylon plastic is essential for ensuring its environmentally responsible use. The sourcing of raw materials, manufacturing processes, and end-of-life considerations all play a crucial role in the overall sustainability of nylon plastic. As consumers and businesses increasingly prioritize sustainable practices, the demand for responsibly sourced and produced nylon is expected to drive further innovations in the industry.

In conclusion, nylon plastic continues to be a valuable and versatile material with a wide range of applications. However, the future trends and innovations in its use for sustainable development are promising. From advancements in 3D printing and recycling technologies to the integration of bio-based alternatives and sustainable supply chains, the potential for nylon plastic to contribute to a more sustainable future is significant. As the industry continues to evolve, it is important to prioritize responsible and innovative approaches to the use of nylon plastic, ensuring its long-term viability and environmental impact.

Conclusion

In conclusion, nylon plastic has proven to be a highly versatile and durable material with a wide range of applications. From its high tensile strength and heat resistance to its flexibility and lightweight properties, nylon plastic is a popular choice in various industries, from fashion to automotive and beyond. Its ability to be molded into different shapes and its resistance to abrasion and chemicals make it an ideal material for a multitude of uses. As new technologies and innovations continue to emerge, it is likely that the versatility and characteristics of nylon plastic will only continue to expand, making it an indispensable material in the modern world.