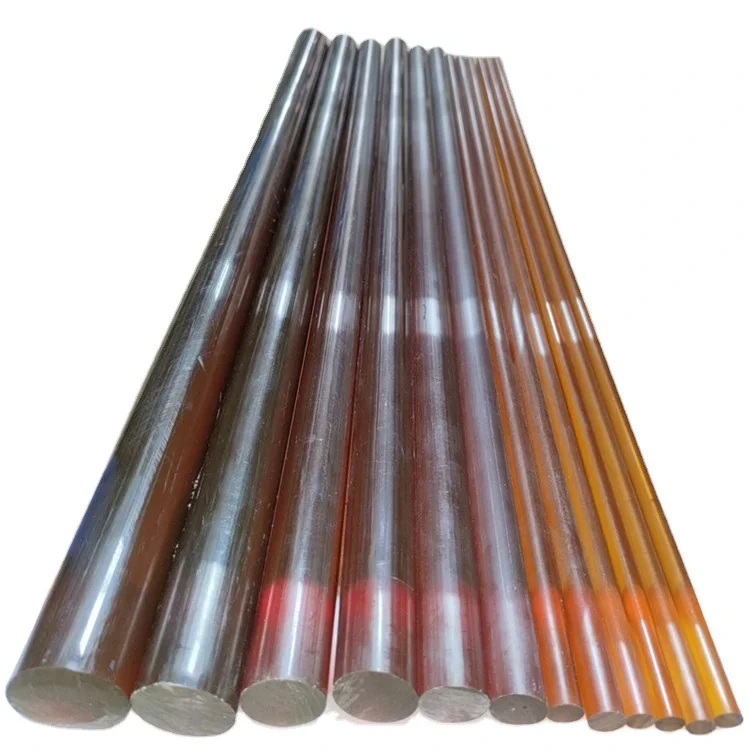

Ultem1000 2300 Polyethylenimine Amber Black PEI Sheet & Rods

ULTEM™ materials, such as ULTEM™ 1000 and ULTEM™ 3000, are specifically designed for extreme environments, providing unmatched safety and reliability for high-stakes industries.

Polyetherimide (PEI), marketed under the brand ULTEM™, is a premium engineering plastic known for its superior thermal, mechanical, and electrical properties. Below is a detailed breakdown of its key attributes to guide consumers in making informed decisions:

Core Features:

- High Thermal Stability: PEI can withstand continuous use at temperatures up to 170°C without losing structural integrity, making it ideal for high-temperature applications.

- Inherent Flame Retardancy: With a UL94 V-0 rating, PEI resists combustion and emits low smoke, ensuring safety in flame-prone environments such as aerospace and electronics.

- Exceptional Mechanical Strength: PEI offers high tensile strength, rigidity, and dimensional stability, even in challenging conditions.

- Excellent Electrical Insulation: PEI’s superior dielectric properties make it an excellent insulator, suitable for high-voltage or electronic components.

- Chemical Resistance: PEI resists a broad range of chemicals, including hydrocarbons, alcohols, and acids, allowing for use in chemically harsh environments.

Function and Applications:

- Aerospace: PEI is used in aircraft interiors, insulation panels, and connectors where flame resistance and durability are paramount.

- Automotive: Commonly used in fuel system components, sensor housings, and high-temperature engine parts that demand strength and heat resistance.

- Medical Devices: Sterilizable medical equipment, including surgical tools and trays, benefit from PEI’s biocompatibility and high heat resistance.

- Electronics: PEI is used for connectors, circuit boards, and electrical housings, where electrical insulation and flame retardancy are critical.

Advantages:

- Long-term Durability: PEI maintains mechanical strength, shape, and performance over time, even under high heat and chemical exposure, reducing the need for frequent replacements.

- Flame Safety & Low Smoke Emission: Its flame-resistant and low-smoke properties make PEI a safe choice for critical applications, especially in confined spaces like aircraft or vehicles.

- Cost Efficiency: Although PEI is a high-end material, its durability, low maintenance, and reduced downtime make it cost-effective over the long term.

Value Proposition:

By choosing ULTEM™ PEI, consumers invest in a material that delivers consistent high performance under extreme conditions. Whether for aerospace, medical, automotive, or electronics, PEI offers unmatched safety, reliability, and long-term value. The combination of its flame resistance, mechanical strength, and thermal stability makes it an optimal choice for industries where failure is not an option.

ESD Ultem1000 PEI: Premium Anti-Static Protection

Our Amber Black ESD Anti-Static Ultem1000 2300 Polyethylenimine PEI Sheet & Rods provide high strength and rigidity at elevated temperatures with long term heat resistance, making them perfect for applications in aerospace, automotive, electronics, food, and medical industries. With excellent dimensional stability and broad chemical resistance, our Ultem® PolyEtherImide (PEI) products are reliable and durable for coil bobbins, water-pump impellers, hot water reservoirs, and more. At Yigao, we provide tailored machining and customization services according to your specific requirements, ensuring top-quality engineering plastics for long-term, good relationships with our customers.

● High-Performance Ultem1000 2300 Polyethylenimine PEI Sheet & Rods

● Dimensionally Stable Ultem1000 2300 Polyethylenimine PEI Sheet & Rods

● Customizable Ultem1000 2300 Polyethylenimine PEI Sheet & Rods

● Reliable Ultem1000 2300 Polyethylenimine PEI Sheet & Rods

Product Display

Superior ESD Protection: Amber Black Ultem1000

ESD Protection with Ultem1000

Amber Black ESD Anti-Static Ultem1000 2300 Polyethylenimine PEI Sheet & Rods are made of high-performance Ultem® PolyEtherImide (PEI) material, offering high strength, rigidity, and long-term heat resistance. The material also provides excellent dimensional stability, broad chemical resistance, and is suitable for applications such as coil bobbins, insulating bushes, water-pump impellers, and hot water reservoirs. With a density of 1.45g/cm3 and temperature resistance of 250-300 degrees, these PEI sheets and rods are ideal for aerospace, automotive, electronics, food, and medical applications, providing tailored machined parts customization processing service for customer's requirements.

◎ Dimensional Stability

◎ Broad Chemical Resistance

◎ Long-Term Heat Resistance

Application Scenario

Material Introduction

The Amber Black ESD Anti-Static Ultem1000 2300 Polyethylenimine (PEI) Sheet & Rods are made from Polyetherimide (PEI), a high-performance polymer known for its strength, rigidity, and long-term heat resistance. This material offers excellent dimensional stability and broad chemical resistance, making it suitable for a wide range of applications including coil bobbins, insulating bushes, hot water reservoirs, and sterilization components. With a density of 1.45g/cm3 and a temperature resistance of 250-300 degrees, these Ultem PEI Sheet & Rods are an ideal choice for aerospace, automotive, electronics, food, and medical applications. Yigao specializes in providing tailored machined parts customization processing service according to customer's drawings or samples, ensuring high-quality and customized solutions for various industries.

◎ Amber Black ESD Anti-Static Ultem1000 2300 Polyethylenimine (PEI) Sheet

◎ Amber Black ESD Anti-Static Ultem1000 2300 Polyethylenimine (PEI) Rods

◎ Polyetheretherketone (PEEK) machined parts

FAQ