The Versatility Of Acrylonitrile Butadiene Styrene (ABS) Plastic: A Material For The Modern Age

Welcome to an exploration of the remarkable versatility of Acrylonitrile Butadiene Styrene (ABS) plastic - a material that has become indispensable in the modern age. From its use in everyday household items to critical components in industries such as automotive and electronics, ABS plastic has proven itself to be a durable, resilient, and adaptable material. Join us as we delve into the countless applications and benefits of ABS plastic, and discover why it continues to be a material of choice in today's rapidly evolving world.

- Introducing ABS Plastic: A Brief Overview of its Composition and Properties

Acrylonitrile butadiene styrene (ABS) plastic is a versatile and widely-used material in the modern age. This article will provide a detailed overview of its composition and properties, shedding light on the reasons behind its popularity and applications.

Composition of ABS Plastic:

ABS is a terpolymer, meaning it is composed of three different monomers - acrylonitrile, butadiene, and styrene. The proportion of these monomers can vary depending on the desired properties of the final plastic. Typically, ABS contains approximately 20-30% acrylonitrile, 5-30% butadiene, and 40-60% styrene. This unique composition gives ABS plastic a combination of properties that make it suitable for a wide range of applications.

Properties of ABS Plastic:

ABS plastic is known for its durability, impact resistance, and heat resistance. It has excellent dimensional stability and can withstand high temperatures without deforming, making it ideal for both indoor and outdoor use. Additionally, ABS is resistant to chemicals, making it suitable for applications where it may come into contact with various substances. It is also a lightweight material, making it easy to handle and manufacture. Furthermore, ABS plastic can be easily molded and extruded, allowing for complex shapes and designs to be created with ease.

Applications of ABS Plastic:

The versatility of ABS plastic makes it a popular choice in various industries. One of its most well-known uses is in the production of consumer goods and electronics. Items such as computer keyboard keys, LEGO bricks, and protective helmets are often made from ABS plastic. Its impact resistance and durability make it suitable for these applications. ABS is also commonly used in the automotive industry for interior and exterior trim components, as well as in the construction industry for pipes and fittings. Additionally, ABS plastic has found its way into the medical field, where its chemical resistance and ease of sterilization make it suitable for use in medical devices and equipment.

In conclusion, acrylonitrile butadiene styrene (ABS) plastic is a versatile and widely-used material due to its unique composition and properties. Its durability, impact resistance, heat resistance, and chemical resistance make it suitable for a wide range of applications, from consumer goods to automotive and medical applications. As technology and manufacturing techniques continue to advance, the versatility of ABS plastic ensures that it will remain a material for the modern age.

- The Role of ABS Plastic in Modern Industry: From Automotive to Consumer Electronics

Acrylonitrile Butadiene Styrene (ABS) plastic is a versatile and widely used material in modern industry, finding applications in various sectors such as automotive, consumer electronics, and many others. Its unique combination of properties makes it an ideal choice for a wide range of products, from car bumpers to computer keyboards.

In the automotive industry, ABS plastic plays a crucial role in improving the safety and performance of vehicles. Its high impact resistance and durability make it an ideal material for use in car bumpers, interior trim, and exterior body panels. ABS plastic is also commonly used in the production of various automotive components, such as dashboards, steering wheel covers, and door panels. Its ability to withstand high temperatures and harsh environments makes it an excellent choice for applications in the automotive sector.

In the consumer electronics industry, ABS plastic is widely used in the production of a wide range of products, including computer casings, keyboards, and other peripherals. Its excellent dimensional stability and resistance to heat and chemicals make it an ideal material for use in electronic devices. ABS plastic also offers good electrical insulation properties, making it a suitable choice for various electronic components.

One of the key advantages of ABS plastic is its ease of processing and ability to be molded into complex shapes. This makes it a cost-effective material for manufacturers seeking to produce intricate designs and components. Its ability to be easily machined, cut, and shaped allows for greater flexibility in design and production, leading to reduced manufacturing costs and time.

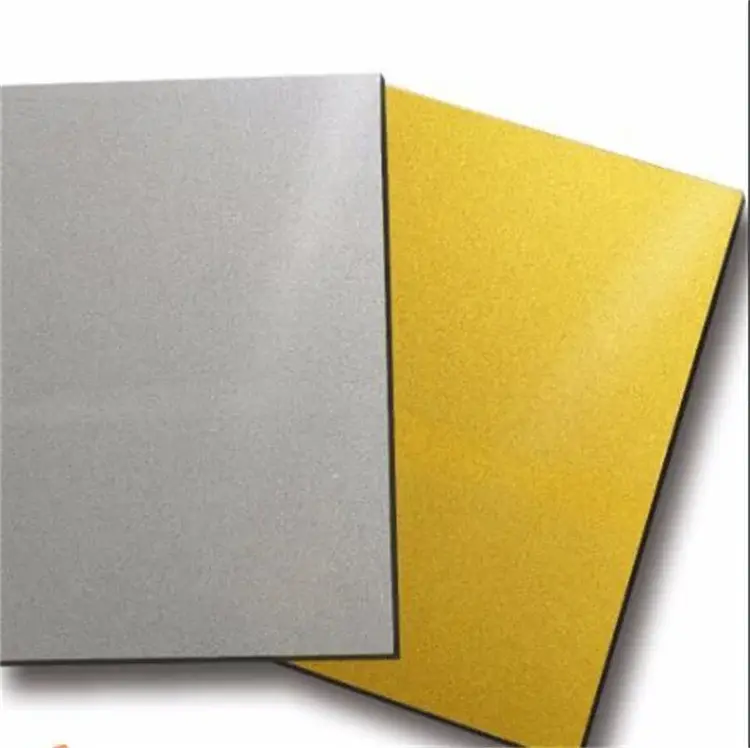

Another important characteristic of ABS plastic is its excellent aesthetic properties. It can be easily colored, painted, and finished to create an attractive and professional appearance. This makes it an ideal choice for products where appearance is a critical factor, such as consumer electronics and household appliances.

In addition to its mechanical and aesthetic properties, ABS plastic also exhibits good chemical resistance, which allows for its use in various harsh environments. It is resistant to a wide range of chemicals, oils, and solvents, making it suitable for applications in the automotive and industrial sectors.

Overall, the versatility of acrylonitrile butadiene styrene (ABS) plastic makes it an essential material for the modern age. Its ability to meet the diverse demands of different industries, coupled with its cost-effectiveness and ease of processing, has made it a preferred choice for manufacturers worldwide. As technology continues to advance and new applications for ABS plastic are discovered, its importance in modern industry will only continue to grow.

- Advantages and Limitations of ABS Plastic: Understanding its Versatility

Acrylonitrile Butadiene Styrene (ABS) plastic is a versatile and widely used material in the modern age. This article aims to explore the advantages and limitations of ABS plastic, as well as to highlight its versatility as a material.

Advantages of ABS Plastic

One of the main advantages of ABS plastic is its strength and durability. It is a tough and impact-resistant material, making it suitable for a wide range of applications, including automotive parts, electronic housings, and consumer goods. This strength also makes ABS plastic ideal for 3D printing, as it can withstand the rigors of the printing process.

In addition to its strength, ABS plastic is also lightweight, which makes it easy to handle and transport. This is particularly important in industries such as automotive and aerospace, where lightweight materials are essential for improving fuel efficiency and reducing emissions.

Another advantage of ABS plastic is its heat resistance. It can withstand high temperatures without deforming or melting, making it suitable for applications where heat resistance is important, such as in the production of kitchen appliances and electronic devices.

Furthermore, ABS plastic is easy to process and can be molded into complex shapes, making it ideal for manufacturing a wide range of products. Its versatility and ease of processing make it a cost-effective material for many industries.

Limitations of ABS Plastic

While ABS plastic offers many advantages, it also has some limitations. One of the main limitations of ABS plastic is its susceptibility to UV rays. Over time, exposure to sunlight can cause ABS plastic to degrade and become brittle, reducing its strength and durability.

Another limitation of ABS plastic is its poor chemical resistance. It is not suitable for applications where it will come into contact with harsh chemicals, as it can degrade and lose its properties.

Furthermore, ABS plastic is not as rigid as some other materials, such as polycarbonate or nylon, which limits its use in certain applications where stiffness is essential.

Understanding the Versatility of ABS Plastic

Despite its limitations, ABS plastic remains a highly versatile material with a wide range of applications. Its strength, durability, and ease of processing make it a popular choice for manufacturers in various industries.

In the automotive industry, ABS plastic is used for interior and exterior components, such as bumpers, trims, and panels. Its impact resistance and lightweight properties make it ideal for these applications.

In the electronics industry, ABS plastic is used for the production of casings and housings for electronic devices, such as laptops, televisions, and mobile phones. Its heat resistance and ease of processing make it a suitable material for these applications.

In the consumer goods industry, ABS plastic is used for a wide range of products, including toys, luggage, and household appliances. Its strength, durability, and ability to be molded into complex shapes make it a versatile material for these applications.

In conclusion, ABS plastic offers a range of advantages, including strength, durability, and heat resistance. However, it also has limitations, such as susceptibility to UV rays and poor chemical resistance. Despite these limitations, ABS plastic remains a versatile and widely used material in the modern age, with applications in industries such as automotive, electronics, and consumer goods. Its versatility and ease of processing make it a valuable material for manufacturers seeking cost-effective and durable solutions.

- Innovations in ABS Plastic: How Research and Development is Expanding its Applications

Acrylonitrile Butadiene Styrene (ABS) plastic has long been celebrated for its versatility and durability. From its humble beginnings as a replacement for traditional materials such as wood and metal, ABS plastic has evolved to become a key player in modern manufacturing and product design. With ongoing research and development, this robust material is continuing to push the boundaries of its applications, revolutionizing industries and consumer products in the process.

One of the key innovations in ABS plastic is its enhanced strength and impact resistance. Through advances in material science and engineering, ABS plastic is now able to withstand greater forces and pressures, making it an ideal choice for applications in the automotive, aerospace, and construction industries. Its ability to maintain its structural integrity under stress has opened up new possibilities for designing and manufacturing components and products that demand reliability and longevity.

Furthermore, research and development have led to breakthroughs in the flame-retardant properties of ABS plastic. This has paved the way for its use in critical applications where fire safety is paramount, such as electrical and electronic devices, appliances, and even in building materials. The ability of ABS plastic to meet stringent safety standards while maintaining its other desirable characteristics makes it an attractive option for a wide range of applications where fire resistance is essential.

In addition to its physical properties, ongoing research and development in ABS plastic have also focused on its aesthetic and surface finish capabilities. With advancements in polymer chemistry and processing technologies, ABS plastic can now be produced with a wider range of colors, textures, and finishes, allowing for greater design flexibility and creativity in product development. This has made ABS plastic a material of choice for consumer goods, consumer electronics, and household appliances, where visual appeal plays a crucial role in consumer acceptance.

Another area of innovation in ABS plastic is its environmental sustainability. With growing concerns about plastic waste and its impact on the environment, researchers and manufacturers have been working to develop sustainable alternatives and recycling processes for ABS plastic. By incorporating recycled materials and exploring new bio-based sources, the environmental footprint of ABS plastic can be reduced, making it a more eco-friendly choice for both manufacturers and consumers.

The versatility of acrylonitrile butadiene styrene plastic is a testament to the ongoing research and development efforts that have expanded its applications in various industries. From its enhanced strength and impact resistance to its improved flame-retardant properties, aesthetic capabilities, and environmental sustainability, ABS plastic continues to prove its value as a material for the modern age. As technology advances and new challenges arise, the potential for further innovations in ABS plastic remains bright, offering exciting possibilities for the future of manufacturing and design.

- The Future of ABS Plastic: Potential for Sustainable and Environmentally Friendly Solutions

Acrylonitrile Butadiene Styrene (ABS) plastic has long been hailed as a versatile and durable material, suitable for a wide range of applications in the modern age. From consumer products to industrial components, ABS plastic has proven its worth time and time again. However, as the world becomes increasingly aware of the impact of plastic on the environment, the future of ABS plastic is being called into question. Can this widely used material transform into a sustainable and environmentally friendly solution? This article explores the potential for ABS plastic to evolve and meet the demands of a more sustainable future.

ABS plastic is a thermoplastic polymer that is known for its high strength, rigidity, and resistance to heat and chemicals. It is commonly used in the manufacture of consumer goods such as electronics, automotive parts, and toys, as well as in the production of industrial components and 3D printing. Its versatility and reliability have made it a go-to material for many industries, but the environmental impact of ABS plastic cannot be ignored.

One of the key challenges in making ABS plastic more sustainable lies in its production process. The raw materials used in the production of ABS plastic, including petroleum and natural gas, are non-renewable resources that contribute to carbon emissions and environmental degradation. Furthermore, the disposal of ABS plastic products at the end of their life cycle presents a significant environmental problem, as traditional plastic waste can take hundreds of years to decompose in landfills.

However, recent advancements in sustainable manufacturing and recycling technologies offer hope for the future of ABS plastic. Researchers and engineers are exploring alternative raw materials to produce ABS plastic, such as bio-based polymers derived from renewable sources like plant oils and agricultural waste. These bio-based ABS plastics have the potential to significantly reduce the environmental impact of ABS production and offer a more sustainable alternative to traditional ABS plastic.

In addition to sustainable production methods, efforts are also being made to improve the recyclability of ABS plastic. Mechanical and chemical recycling processes can be used to break down used ABS plastic products into their original raw materials, allowing them to be used in the production of new plastic products. Furthermore, advances in 3D printing technology are enabling the on-site recycling of ABS plastic waste, reducing the need for virgin plastic materials and minimizing the environmental footprint of 3D printing processes.

The future of ABS plastic as a sustainable and environmentally friendly material also lies in the hands of consumers and industries. By embracing the use of recycled ABS plastic and supporting the development of bio-based ABS alternatives, businesses and consumers can play a crucial role in reducing the environmental impact of ABS plastic. Moreover, the adoption of circular economy principles, which prioritize the reusability and recyclability of materials, can further drive the transformation of ABS plastic into a more sustainable solution for the modern age.

In conclusion, the versatility of Acrylonitrile Butadiene Styrene (ABS) plastic presents significant potential for sustainable and environmentally friendly solutions. By embracing sustainable production methods, improving recyclability, and supporting the development of bio-based alternatives, ABS plastic can evolve to meet the demands of a more sustainable future. With concerted efforts from researchers, industries, and consumers, ABS plastic can maintain its versatility while minimizing its environmental impact, paving the way for a more sustainable use of this essential material in the modern age.

Conclusion

In conclusion, it is clear that ABS plastic is a highly versatile and valuable material for a wide range of modern day applications. Its unique combination of strength, flexibility, and resistance to heat and chemicals make it a top choice for manufacturers in industries such as automotive, electronics, and consumer goods. With its ability to be easily molded and colored, ABS plastic offers endless possibilities for creative design and innovation. As technology continues to advance, it is likely that we will see even more uses for this remarkable material in the future. ABS plastic truly is a material for the modern age, and its impact on the way we live and work is undeniable.