The Advantages And Uses Of ABS Acrylonitrile Butadiene Styrene In Modern Engineering

Are you a modern engineer looking to optimize your projects? Look no further! "The Advantages and Uses of ABS Acrylonitrile Butadiene Styrene in Modern Engineering" is a comprehensive guide to understanding the benefits and applications of this versatile and durable material. Whether you're involved in automotive, construction, or consumer electronics, this article will provide valuable insights on how ABS can enhance your engineering endeavors. Join us as we explore the potential of ABS in modern engineering and unlock new possibilities for your projects.

- Introduction to ABS Acrylonitrile Butadiene Styrene

to ABS Acrylonitrile Butadiene Styrene

ABS, which stands for Acrylonitrile Butadiene Styrene, is a versatile and widely used thermoplastic polymer. It is a terpolymer compound composed of three monomers: acrylonitrile, butadiene, and styrene. ABS is known for its excellent mechanical properties, impact resistance, and heat resistance, making it ideal for a wide range of applications in modern engineering.

One of the key advantages of ABS is its high strength and rigidity, which makes it suitable for applications that require durable and robust materials. Additionally, ABS has excellent impact resistance, making it an ideal choice for products that are subject to impact or rough handling. Its heat resistance properties also make it suitable for use in applications that require exposure to high temperatures.

Another important characteristic of ABS is its ease of processing and molding. ABS can be easily molded and shaped into complex geometries, making it a popular choice for injection molding and 3D printing. This versatility in processing makes ABS an attractive option for engineers and designers looking to create intricate and detailed parts and components.

ABS also offers good chemical resistance, making it suitable for use in harsh environments where exposure to chemicals is a concern. Its resistance to many acids, alkalis, and other chemicals makes it an ideal choice for applications in the automotive, aerospace, and electronics industries.

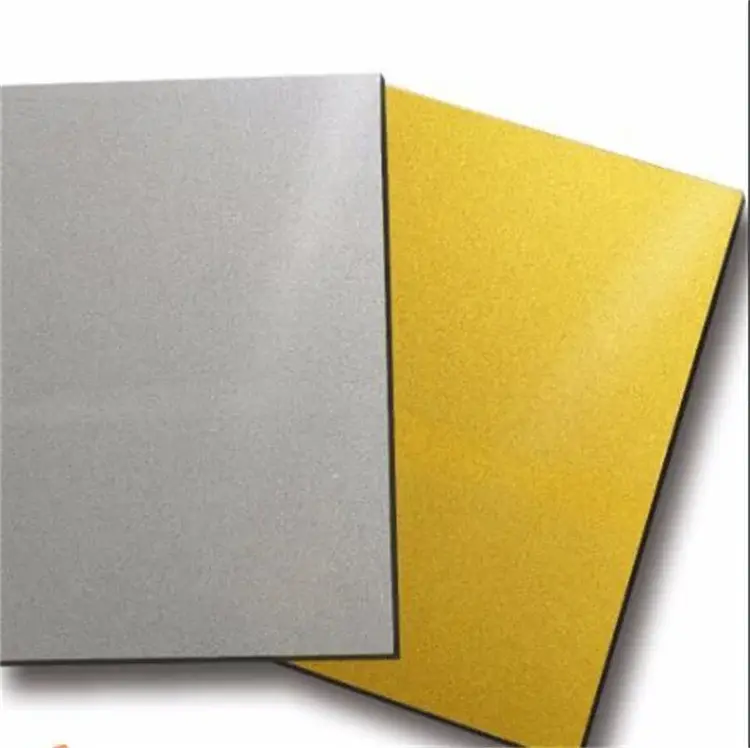

In addition to its physical and mechanical properties, ABS is also known for its aesthetic appeal. It can be easily colored, painted, or plated to achieve the desired finish, making it a popular choice for consumer products and electronic devices. Its ability to maintain its appearance and color over time makes it a preferred material for products that require a durable and attractive finish.

The uses of ABS are diverse and widespread. In the automotive industry, ABS is commonly used for exterior and interior trim components, dashboard panels, and wheel covers. Its impact resistance and ability to maintain its appearance make it an ideal material for these applications. In the electronics industry, ABS is used for the housings of various electronic devices, such as computer casings, televisions, and home appliances, due to its good electrical insulation properties and aesthetic appeal.

In the construction industry, ABS is used for pipes, fittings, and other building materials due to its durability, resistance to chemicals, and ease of installation. In the medical industry, ABS is used for medical devices and equipment due to its ability to withstand sterilization processes and its biocompatibility.

In conclusion, ABS Acrylonitrile Butadiene Styrene is a versatile and widely used material in modern engineering. Its excellent mechanical properties, impact resistance, heat resistance, and ease of processing make it an ideal choice for a wide range of applications in various industries. With its aesthetic appeal, durability, and chemical resistance, ABS continues to be a popular material for a diverse range of products and components.

- Advantages of ABS in Modern Engineering

ABS, also known as Acrylonitrile Butadiene Styrene, is a widely used thermoplastic in modern engineering. Its versatility and numerous advantages make it a popular choice for a wide range of applications. In this article, we will explore the advantages of ABS in modern engineering and its uses in various industries.

One of the key advantages of ABS is its high impact resistance. This makes it an ideal material for applications that require durability and toughness. Its ability to withstand heavy impacts without breaking or shattering makes it suitable for use in products such as protective gear, automotive parts, and electronic housings. Its impact resistance also makes it a preferred choice for consumer products, such as luggage and sports equipment, where durability is essential.

Another advantage of ABS is its excellent moldability. It can be easily molded and shaped into complex geometries, making it a versatile material for manufacturing processes. This allows for the production of intricate and customized parts, which is highly beneficial in the engineering and manufacturing industries. Additionally, its moldability also enables the production of lightweight components, which is crucial for applications where weight reduction is a priority.

ABS also exhibits good chemical resistance, making it suitable for use in harsh environments. It is resistant to many chemicals, oils, and greases, which makes it an ideal material for applications in the automotive, chemical processing, and industrial equipment industries. Its resistance to chemicals also extends its lifespan, making it a cost-effective material for various engineering applications.

Furthermore, ABS has excellent thermal stability, allowing it to maintain its mechanical properties at elevated temperatures. This makes it suitable for use in applications where exposure to high temperatures is common, such as automotive engine components, electronic enclosures, and household appliances. Its ability to withstand high temperatures without deforming or losing its properties further enhances its utility in modern engineering.

ABS is also known for its good electrical insulation properties, making it an ideal material for electronic and electrical applications. Its ability to insulate against electrical currents and resist electrical breakdown makes it a preferred choice for the production of electrical enclosures, connectors, and housings. Its electrical insulation properties also make it a reliable material for use in electronic devices and appliances.

In conclusion, ABS, or Acrylonitrile Butadiene Styrene, offers numerous advantages in modern engineering. From its high impact resistance and excellent moldability to its chemical resistance and thermal stability, ABS is a versatile material that finds application in various industries. Its properties make it an ideal choice for a wide range of engineering applications, contributing to the advancement of modern technology and industry.

- Uses of ABS in Modern Engineering Applications

ABS, or Acrylonitrile Butadiene Styrene, is a versatile and widely used thermoplastic polymer that has found a multitude of applications in modern engineering. This article will explore the many uses and advantages of ABS in various engineering applications, highlighting its unique properties and benefits.

ABS is known for its exceptional strength, rigidity, and impact resistance, making it an ideal material for a wide range of engineering applications. One of the key uses of ABS is in the manufacturing of automotive components. Its ability to withstand high impact forces and harsh environmental conditions makes it an excellent choice for the production of bumpers, trim components, and interior parts in automobiles. ABS is also commonly used in the production of motorcycle helmets and protective gear, where its impact resistance and durability are critical for ensuring the safety of riders.

In addition to its use in the automotive industry, ABS is also widely utilized in the manufacture of consumer electronics. Its high strength and resistance to heat and chemicals make it an ideal material for housing and casing components in electronic devices such as laptop computers, cameras, and home appliances. ABS is also a popular choice for the production of computer keyboard keys and mouse housings due to its durability and resistance to wear and tear.

Another important application of ABS in modern engineering is in the field of construction and architecture. ABS is often used in the production of pipes, fittings, and valve components for plumbing systems, as well as in the manufacture of architectural panels, decorative trim, and lighting fixtures. Its resistance to heat, chemicals, and impact make it an excellent material for these applications, ensuring long-lasting performance and durability in various environmental conditions.

The versatility of ABS also extends to the field of 3D printing, where it is commonly used as a filament material for producing prototypes and functional parts. Its ease of use, low cost, and ability to be molded into complex shapes make ABS a preferred choice for 3D printing applications in engineering and product development.

Furthermore, ABS is utilized in the production of various household and consumer products, including toys, luggage, and sporting goods. Its ability to be molded into intricate shapes and designs, as well as its resistance to impact and wear, make it a popular choice for these applications.

In conclusion, ABS, or Acrylonitrile Butadiene Styrene, is a highly versatile and durable thermoplastic polymer that has found numerous uses in modern engineering applications. Its exceptional strength, impact resistance, and durability make it an ideal material for automotive components, consumer electronics, construction materials, 3D printing, and household products. As technology and engineering continue to evolve, the uses of ABS are likely to expand even further, solidifying its importance as a key material in modern engineering.

- Properties of ABS that Make it Suitable for Engineering

ABS, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer that has become widely popular in the field of engineering due to its unique properties. These properties make ABS a suitable material for a wide range of engineering applications, including but not limited to, automotive parts, electronic housings, and consumer goods. In this article, we will explore the advantages and uses of ABS in modern engineering and why it has become such a popular material in the industry.

One of the key properties of ABS that make it suitable for engineering is its excellent impact resistance. ABS exhibits a high impact strength, making it ideal for applications where the material may be subjected to sudden or repeated impacts. This property makes ABS a popular choice for automotive parts, such as bumpers and trim components, where impact resistance is crucial for safety and durability.

Furthermore, ABS possesses good dimensional stability, meaning it retains its shape and dimensions even when subjected to changes in temperature or humidity. This property is essential in engineering applications where precise measurements and tolerances are required, such as in the production of electronic housings and enclosures. The dimensional stability of ABS ensures that the final product will maintain its shape and functionality under different environmental conditions.

In addition to its impact resistance and dimensional stability, ABS also offers good chemical resistance. This means that it can withstand exposure to a wide range of chemicals, making it suitable for applications where the material may come into contact with corrosive substances. This property makes ABS a popular choice for the production of chemical tanks and piping systems in industrial settings.

Another advantageous property of ABS is its excellent heat resistance. ABS can withstand high temperatures without deforming or losing its structural integrity, making it ideal for applications that require exposure to heat, such as automotive components and electrical enclosures. This heat resistance also makes ABS a suitable material for 3D printing, where the material needs to withstand the high temperatures generated during the printing process.

Moreover, ABS is easily machinable and can be easily modified and fabricated to meet specific engineering requirements. This property allows for the production of complex and intricate parts with ease, making ABS a versatile material for a wide range of engineering applications.

In conclusion, the unique properties of ABS, including its impact resistance, dimensional stability, chemical resistance, heat resistance, and machinability, make it a highly suitable material for modern engineering applications. Its versatility and durability have made it a popular choice for a wide range of industries, from automotive and electronics to consumer goods and industrial equipment. As technology continues to advance, it is likely that the uses of ABS in engineering will only continue to expand, solidifying its place as a key material in the field.

- Future Prospects of ABS in the Engineering Industry

ABS (Acrylonitrile Butadiene Styrene) has become an integral material in the engineering industry due to its various advantages and uses. In this article, we will explore the future prospects of ABS in the engineering industry, and how it continues to play a crucial role in modern engineering.

One of the key advantages of ABS in the engineering industry is its high impact resistance. This makes it an ideal choice for applications where durability and strength are essential. From automotive components to electronic enclosures, ABS is widely used in various engineering applications due to its ability to withstand impact and mechanical stress. As the engineering industry continues to evolve, the demand for durable and impact-resistant materials such as ABS is expected to grow.

Moreover, the versatility of ABS makes it a valuable material in the engineering industry. It can be easily molded and shaped into complex designs, making it suitable for a wide range of applications. Whether it’s for consumer goods, machinery parts, or even medical devices, ABS has proven to be a versatile material that can adapt to the evolving needs of the engineering industry. This versatility ensures that ABS will continue to be in demand for diverse engineering applications in the future.

ABS also offers excellent dimensional stability, which is crucial in engineering applications where tight tolerances and precise measurements are essential. This makes it a preferred choice for manufacturing components and parts that require high precision and accuracy. As the engineering industry continues to push the boundaries of innovation, the need for materials that can maintain dimensional stability under varying conditions will only increase, making ABS a valuable resource for future engineering prospects.

Furthermore, ABS has excellent chemical and thermal resistance, making it suitable for applications where exposure to harsh environments is a concern. From industrial equipment to aerospace components, ABS is utilized in various engineering applications where resistance to chemicals and high temperatures is necessary. As industries continue to advance and explore new frontiers, the demand for materials like ABS that can withstand extreme conditions will only continue to rise.

In conclusion, the future prospects of ABS in the engineering industry are highly promising. Its high impact resistance, versatility, dimensional stability, and resistance to chemicals and high temperatures make it an invaluable material for modern engineering applications. As the engineering industry continues to evolve and innovate, the demand for ABS is expected to grow, making it a crucial component in shaping the future of engineering. ABS is not just a material of the present, but also a material that will play a vital role in the future of engineering.

Conclusion

ABS, or Acrylonitrile Butadiene Styrene, has proven to be a versatile and valuable material in modern engineering. In this article, we have explored the many advantages and uses of ABS, from its excellent strength and impact resistance to its ease of fabrication and wide range of applications in various industries. Whether it's in the automotive, electronics, or construction sectors, ABS has become an indispensable material for creating durable and efficient products. As technology continues to advance, so too will the uses of ABS, making it an essential component in the ever-evolving field of modern engineering. With its numerous benefits and practical applications, ABS is undoubtedly a material worth considering for any engineering project. As we look to the future, it's clear that ABS will continue to play a critical role in shaping the world of engineering.