Exploring The Versatility Of Plastic Rods: A Comprehensive Guide

Welcome to our comprehensive guide on exploring the versatility of plastic rods! Whether you're a DIY enthusiast, a hobbyist, or a professional in need of a reliable and adaptable material, this article is designed to enlighten you on the endless possibilities and uses of plastic rods. From their diverse applications in various industries to their potential for creative and practical projects, join us as we delve into the countless ways plastic rods can enhance and elevate your work. Whether you're a beginner or an expert, this guide will provide you with the knowledge and inspiration you need to unlock the full potential of plastic rods. So, let's embark on this journey together and discover the endless potential of this versatile material!

- Understanding the Composition and Properties of Plastic Rods

Plastic rods are essential components in a wide range of industries and applications. They are versatile, durable, and can be used for a variety of purposes. Understanding the composition and properties of plastic rods is crucial for anyone working with these materials. In this comprehensive guide, we will explore the versatility of plastic rods, delving into their composition, properties, and the various applications in which they are used.

Composition of Plastic Rods

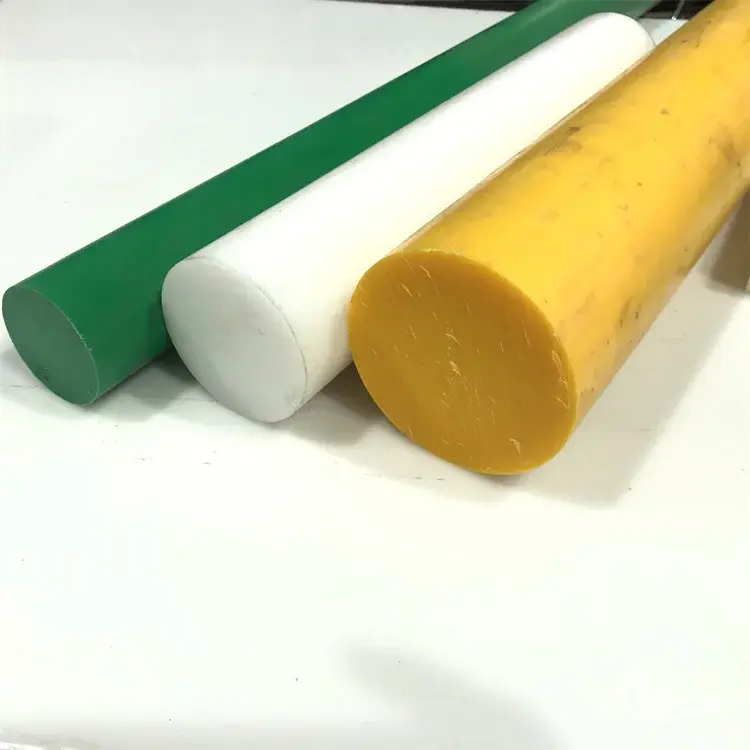

Plastic rods are typically made from a variety of thermoplastic materials, including polyethylene, nylon, polypropylene, and PVC, among others. These materials are chosen for their specific properties, such as strength, flexibility, and resistance to chemicals and impact. The composition of the plastic rods can also be modified to enhance certain properties, such as adding fillers or reinforcements to increase strength and stiffness.

Properties of Plastic Rods

Plastic rods exhibit a wide range of properties that make them suitable for diverse applications. They are lightweight, yet strong, making them ideal for structural applications. They are also highly resistant to corrosion, moisture, and chemicals, making them suitable for use in harsh environments. Additionally, plastic rods can be engineered to have specific properties, such as flame retardancy or electrical conductivity, to meet the requirements of different applications.

Applications of Plastic Rods

The versatility of plastic rods makes them suitable for a wide range of applications across various industries. In the construction industry, plastic rods are used for structural support, insulation, and electrical conduit. In the automotive industry, they are used for engine components, interior trim, and body panels. In the medical industry, plastic rods are used for surgical instruments, prosthetic limbs, and medical devices. They are also used in recreational equipment, household appliances, and consumer goods.

Choosing the Right Plastic Rod

When selecting plastic rods for a specific application, it is essential to consider the properties and composition of the materials. Factors such as temperature resistance, chemical compatibility, mechanical strength, and electrical properties should be evaluated to ensure that the plastic rods will perform as required. Additionally, considerations such as color, size, and surface finish may also be important, depending on the application.

In conclusion, plastic rods are versatile materials with a wide range of properties and applications. Understanding the composition and properties of plastic rods is essential for selecting the right materials for specific applications. Whether used in construction, automotive, medical, or consumer goods, plastic rods offer unique advantages and can be tailored to meet specific performance requirements. By exploring the versatility of plastic rods, we can better appreciate their importance in modern industry and technology.

- Applications of Plastic Rods in Various Industries

Plastic rods are a versatile material that finds applications in various industries due to their numerous beneficial properties. From engineering to manufacturing, plastic rods are utilized in a wide range of applications, making them an essential component in several industries.

The engineering industry is one of the primary sectors where plastic rods are extensively used. These rods are employed in the production of various mechanical components such as gears, bearings, and bushings. Their high strength-to-weight ratio and resistance to corrosion make them ideal for use in heavy-duty machinery. Additionally, plastic rods have excellent insulating properties, making them suitable for use in electrical and electronic equipment.

In the automotive industry, plastic rods are used in the production of components such as bumpers, fenders, and interior trim. Their lightweight nature helps to reduce the overall weight of the vehicle, thereby improving fuel efficiency. Furthermore, plastic rods are highly durable and can withstand extreme weather conditions, making them an ideal material for automotive applications.

The construction industry also benefits from the versatility of plastic rods. These rods are commonly used in the production of construction materials such as pipes, fittings, and insulation. Their resistance to chemicals and moisture makes them well-suited for use in plumbing and HVAC systems. Additionally, plastic rods are lightweight and easy to install, making them a preferred choice for construction projects.

Plastic rods are extensively used in the medical and pharmaceutical industries due to their excellent biocompatibility and resistance to sterilization processes. They are employed in the production of medical devices, surgical instruments, and packaging materials. The flexibility and durability of plastic rods make them ideal for use in these critical applications, where hygiene and safety are of utmost importance.

The marine industry also relies on the versatility of plastic rods for various applications. They are used in the production of marine hardware, boat components, and underwater structures. Plastic rods are resistant to saltwater and corrosion, making them an ideal material for use in marine environments. Their ability to withstand harsh conditions makes them essential for maintaining the integrity of marine structures.

In the aerospace industry, plastic rods are utilized in the production of lightweight components for aircraft and spacecraft. Their high strength-to-weight ratio and resistance to extreme temperatures make them suitable for use in aerospace applications. Additionally, the flexibility of plastic rods allows for the creation of complex and aerodynamic designs, contributing to improved performance and efficiency in aerospace engineering.

In conclusion, the versatility of plastic rods makes them an essential material in various industries. From engineering to aerospace, these rods are utilized in a wide range of applications due to their beneficial properties such as strength, durability, and resistance to corrosion. As industries continue to innovate and evolve, the demand for plastic rods is expected to increase, further solidifying their importance in modern manufacturing and engineering processes.

- Advantages and Disadvantages of Using Plastic Rods

Plastic rods are a versatile and widely used material in various industries due to their numerous advantages. However, there are also drawbacks to using plastic rods that must be considered. This comprehensive guide will explore the advantages and disadvantages of using plastic rods, providing valuable insights for those considering their use in a range of applications.

Advantages of Using Plastic Rods:

1. Versatility: Plastic rods are incredibly versatile and can be used in a wide range of applications, including construction, manufacturing, and DIY projects. Their versatility makes them a popular choice for many different industries.

2. Lightweight: One of the key advantages of plastic rods is their lightweight nature. This makes them easy to handle and transport, as well as reducing the overall weight of the final product. This can be particularly beneficial in industries where weight is a key consideration, such as aerospace or automotive manufacturing.

3. Durable: Plastic rods are incredibly durable and resistant to corrosion, making them suitable for use in harsh environments. They are also resistant to chemicals, making them an ideal choice for applications where exposure to corrosive substances is a concern.

4. Cost-Effective: Plastic rods are generally more cost-effective than alternative materials such as metal or wood. This can make them an attractive option for businesses looking to reduce production costs without compromising on quality.

5. Low Maintenance: Plastic rods require minimal maintenance compared to other materials, making them a convenient and low-maintenance option for many applications.

Disadvantages of Using Plastic Rods:

1. Environmental Impact: One of the key drawbacks of using plastic rods is their negative impact on the environment. Plastic is non-biodegradable and can take hundreds of years to decompose, leading to pollution and environmental damage. This is a significant concern for many businesses and industries, particularly those with a focus on sustainability and environmental responsibility.

2. Limited Strength: While plastic rods are durable, they generally have lower strength and rigidity compared to metal or wood. This can limit their use in high-stress applications or in situations where high levels of strength are required.

3. Temperature Sensitivity: Plastic rods can be sensitive to temperature fluctuations, with some types of plastic becoming brittle in cold temperatures and softening in hot temperatures. This can limit their use in extreme temperature environments.

4. Limited Aesthetic Appeal: While plastic rods are available in a range of colors and finishes, they may not have the same aesthetic appeal as alternative materials such as wood or metal. This can be a consideration for applications where visual appearance is important.

In conclusion, plastic rods are a versatile and cost-effective material with numerous advantages, including versatility, lightweight nature, durability, and low maintenance. However, it's important to consider the potential drawbacks, such as their environmental impact, limited strength, temperature sensitivity, and limited aesthetic appeal. Ultimately, the decision to use plastic rods will depend on the specific requirements of the application and the priorities of the business or industry in question.

- Choosing the Right Type of Plastic Rod for Your Project

Plastic rods are an incredibly versatile and useful material for a wide range of projects, from DIY crafts to industrial applications. However, with so many different types of plastic rods available, choosing the right one for your specific project can be a daunting task. In this comprehensive guide, we will explore the various types of plastic rods on the market and provide you with the information you need to make an informed decision.

When it comes to selecting the right type of plastic rod for your project, there are several key factors to consider. These include the specific requirements of your project, the properties of the plastic material, and the intended use of the finished product. By taking these factors into account, you can ensure that you select the best plastic rod for your needs.

One of the most important considerations when choosing a plastic rod is the material it is made from. There are many different types of plastic materials available, each with its own unique properties and characteristics. Some common types of plastic rods include acrylic, polycarbonate, PVC, and nylon. Each of these materials has its own strengths and weaknesses, so it is important to carefully consider the specific requirements of your project before making a decision.

For example, if you are working on a project that requires a high degree of transparency, acrylic may be the best choice for you. Acrylic plastic rods are known for their exceptional clarity and light-transmitting properties, making them ideal for applications such as light fixtures, display cases, and signage. On the other hand, if you need a plastic rod with high impact resistance and durability, polycarbonate may be a better option. Polycarbonate plastic rods are incredibly strong and tough, making them suitable for applications such as machine guards, protective barriers, and impact-resistant windows.

In addition to the material, it is also important to consider the specific properties of the plastic rod, such as its tensile strength, temperature resistance, and chemical resistance. These properties can vary significantly from one type of plastic material to another, so it is important to carefully evaluate your project's requirements to ensure that you select a plastic rod with the appropriate properties.

Once you have identified the specific requirements of your project and the properties you need in a plastic rod, it is time to consider the intended use of the finished product. For example, if your project involves outdoor applications, you will need a plastic rod that is resistant to UV radiation and weathering. In this case, PVC or polycarbonate plastic rods may be the best choice, as both materials offer excellent weather resistance and UV stability.

In conclusion, plastic rods are a versatile and useful material for a wide range of projects. By carefully considering the specific requirements of your project, the properties of the plastic material, and the intended use of the finished product, you can select the right type of plastic rod for your needs. Whether you are working on a DIY project at home or an industrial application, choosing the right plastic rod is essential for achieving the best results.

- Maintenance and Care Tips for Plastic Rods

Plastic rods are a versatile and widely used material in various industries. From construction to manufacturing, plastic rods serve a multitude of purposes, making them an essential component in many applications. However, in order to ensure the longevity and optimal performance of plastic rods, proper maintenance and care are crucial. In this comprehensive guide, we will explore the versatility of plastic rods and provide valuable tips for their maintenance and care.

One of the key attributes of plastic rods is their durability and resistance to corrosion. This makes them an ideal choice for use in outdoor settings, as they can withstand harsh weather conditions without deteriorating. However, to maintain their integrity, it is important to regularly clean plastic rods to remove any dirt or debris that may accumulate on their surface. A simple solution of mild soap and water can be used to gently scrub the rods, followed by a thorough rinse to ensure all residue is removed.

In addition to cleaning, it is essential to protect plastic rods from excessive heat or direct sunlight, as prolonged exposure can cause them to warp or become brittle. When storing plastic rods, it is important to keep them in a cool, dry place away from any heat sources. If the rods are to be used outdoors, it is advisable to apply a UV-resistant coating to protect them from the sun’s harmful rays.

Furthermore, proper handling of plastic rods is crucial to prevent any damage or deformation. When transporting or installing plastic rods, it is important to use appropriate handling equipment and techniques to ensure they remain in pristine condition. Avoid dropping or dragging the rods, as this can cause them to become scratched or dented, compromising their structural integrity.

Another important aspect of maintaining plastic rods is to regularly inspect them for any signs of wear or damage. Cracks, scratches, or other imperfections should be addressed promptly to prevent further deterioration. In some cases, minor repairs can be made using plastic welding techniques or adhesives specifically designed for plastic materials. For more extensive damage, it may be necessary to replace the affected rods to prevent compromise of the overall structure or application.

When it comes to the versatility of plastic rods, their applications are vast and diverse. In construction, plastic rods are often used for reinforcement in concrete structures, providing added strength and flexibility. In manufacturing, plastic rods are commonly used in the production of machinery, equipment, and components due to their lightweight and durable nature. Additionally, plastic rods are also utilized in the creation of signage, display fixtures, and various types of craft projects, showcasing their adaptability in a wide range of settings.

In conclusion, plastic rods are a versatile and indispensable material with a myriad of uses. They offer durability, resistance to corrosion, and flexibility, making them an ideal choice for numerous applications. By following proper maintenance and care tips, such as regular cleaning, protection from heat and sunlight, proper handling, and regular inspection, the longevity and performance of plastic rods can be ensured. Whether in construction, manufacturing, or creative projects, plastic rods continue to be a valuable and versatile material.

Conclusion

In conclusion, plastic rods are incredibly versatile and have a wide range of practical applications across various industries. From construction and engineering to crafting and DIY projects, these rods offer durability, flexibility, and affordability. By understanding the different types of plastics and their unique properties, individuals and businesses can make informed decisions when selecting plastic rods for their specific needs. Whether you are looking for a lightweight and weather-resistant material or a strong and impact-resistant option, plastic rods are a reliable choice. As technology and innovation continue to evolve, it is exciting to see how plastic rods will continue to adapt and meet the ever-changing demands of the modern world.