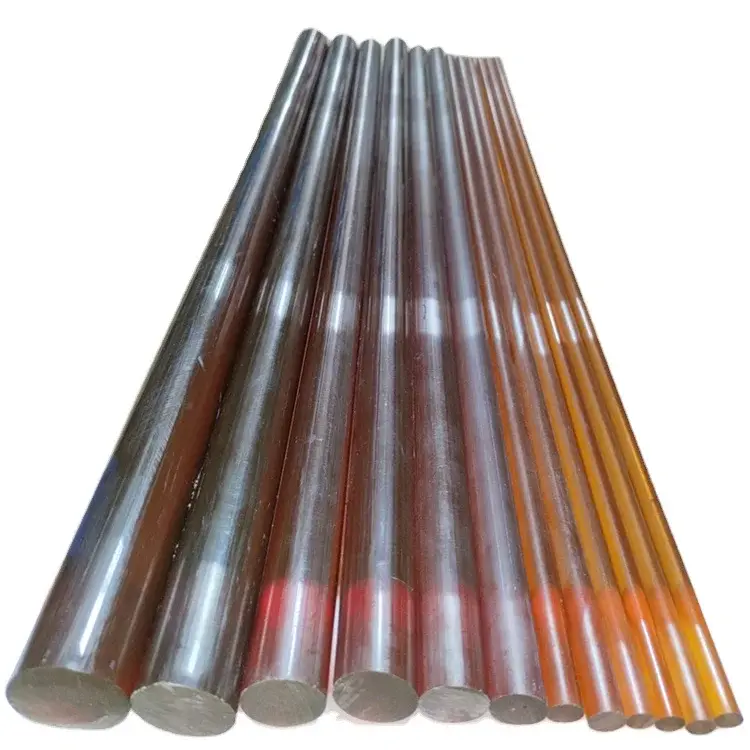

Exploring The Versatility Of PEI Plastic Material

Welcome to our exploration of the versatility of PEI plastic material! In this article, we will delve into the countless applications and benefits of this innovative material, from its use in medical devices and electronics to its impact on various industries. Join us as we uncover the endless possibilities of PEI plastic and its potential to revolutionize the way we approach manufacturing and design. Whether you're a professional in the field or simply curious about the latest advancements in plastics, this article is sure to expand your knowledge and inspire new ideas.

Understanding the Properties of PEI Plastic Material

PEI, or polyetherimide, is a high-performance plastic material that is known for its exceptional combination of mechanical, thermal, and electrical properties. This versatile material has become increasingly popular in various industries due to its unique characteristics and advantages.

One of the key properties of PEI plastic material is its high strength and rigidity. This makes it an ideal choice for applications that require structural integrity and stability, such as in the production of medical devices, automotive components, and electronic parts. The material’s ability to maintain its mechanical properties at elevated temperatures also makes it suitable for use in high-temperature environments.

In addition to its strength and rigidity, PEI plastic material is also known for its excellent thermal resistance. It can withstand continuous exposure to temperatures up to 340°F, making it suitable for use in applications where heat resistance is essential. This makes it a popular choice for components used in automotive and aerospace industries, where exposure to high temperatures is common.

Furthermore, PEI plastic material exhibits good electrical properties, making it suitable for use in applications that require excellent electrical insulation. Its high dielectric strength and low moisture absorption make it an ideal choice for electronic components, electrical connectors, and insulators.

Another important property of PEI plastic material is its excellent chemical resistance. It is resistant to a wide range of chemicals, including acids, bases, and hydrocarbons, making it suitable for use in harsh chemical environments. This makes it a preferred material for applications in the chemical processing industry, where resistance to corrosion and chemical exposure is crucial.

Moreover, PEI plastic material is known for its dimensional stability and low creep, which means that it retains its shape and size over time when subjected to mechanical stress. This makes it suitable for use in precision components and parts that require tight tolerances and minimal deformation.

In conclusion, PEI plastic material is a versatile material that offers a unique combination of properties, making it suitable for a wide range of applications across various industries. Its high strength, thermal resistance, electrical properties, chemical resistance, and dimensional stability make it an ideal choice for demanding applications that require reliable and high-performance materials. As the demand for high-performance plastics continues to grow, the versatility of PEI plastic material makes it an attractive option for manufacturers and engineers looking for a reliable and durable material for their applications.

Applications of PEI Plastic in Various Industries

Polyetherimide (PEI) plastic is a versatile and high-performance material that is widely used in various industries due to its exceptional properties. In this article, we will explore the applications of PEI plastic in different industries and understand why it is an ideal choice for various applications.

In the aerospace industry, PEI plastic is known for its excellent chemical resistance, high strength, and heat resistance, making it an ideal material for manufacturing interior components, brackets, and structural components in aircraft. Its ability to withstand high temperatures and harsh environmental conditions makes it a preferred choice for aerospace applications.

In the medical industry, PEI plastic is widely used in the manufacturing of medical devices and equipment due to its biocompatibility, sterilization resistance, and transparency. It is used in applications such as surgical instruments, dental equipment, and medical device housings. The ability of PEI plastic to withstand repeated sterilization cycles without degradation makes it an ideal material for medical applications.

The automotive industry also makes extensive use of PEI plastic due to its high strength, dimensional stability, and resistance to automotive fluids. It is commonly used for manufacturing components such as sensors, connectors, and electrical housings due to its excellent electrical properties. The ability of PEI plastic to maintain its mechanical properties at high temperatures also makes it a suitable material for under-the-hood applications in automobiles.

In the electronics industry, PEI plastic is used for manufacturing components such as connectors, sockets, and semiconductor equipment due to its excellent dielectric properties, flame resistance, and dimensional stability. Its ability to withstand high temperatures and harsh environmental conditions makes it a preferred choice for electronic applications where reliability and performance are critical.

In the industrial and consumer goods industry, PEI plastic is used for a wide range of applications such as food processing equipment, electrical components, and consumer appliances. Its excellent chemical resistance and mechanical properties make it suitable for applications where exposure to harsh chemicals and high temperatures is common.

In conclusion, the versatility of PEI plastic material makes it an ideal choice for various industries. Its exceptional properties such as high strength, heat resistance, chemical resistance, and biocompatibility make it a preferred material for a wide range of applications. As technology continues to advance, the demand for PEI plastic is expected to grow as industries continue to explore and capitalize on its unique properties.

Advantages and Limitations of PEI Plastic Material

PEI, or polyetherimide, is a high-performance thermoplastic known for its exceptional temperature resistance, chemical resistance, and mechanical properties. It is widely used in various industries, including aerospace, automotive, medical, and electronics, due to its unique combination of advantages. However, like any material, PEI also has its limitations that need to be considered when choosing it for a specific application.

Advantages of PEI Plastic Material

1. High Temperature Resistance: One of the key advantages of PEI is its ability to withstand high temperatures. It has a continuous use temperature of up to 180°C, making it suitable for applications that require exposure to elevated temperatures, such as automotive under-the-hood components and electronic devices.

2. Chemical Resistance: PEI is resistant to a wide range of chemicals, including hydrocarbons, alcohols, and halogenated and aromatic hydrocarbons. This makes it an ideal choice for applications where exposure to aggressive chemicals is expected, such as medical devices and chemical processing equipment.

3. Dimensional Stability: PEI exhibits excellent dimensional stability, meaning it retains its shape and size in various environmental conditions. This property is especially beneficial in precision engineering applications where tight tolerances and dimensional accuracy are critical.

4. High Strength and Stiffness: PEI offers exceptional mechanical properties, including high strength and stiffness, making it suitable for structural components in aerospace and automotive applications.

5. Flame Retardancy: PEI is inherently flame retardant, meaning it does not support combustion and will self-extinguish when the flame source is removed. This property is essential for applications where fire safety is a concern, such as electrical components and consumer electronics.

Limitations of PEI Plastic Material

1. Cost: Compared to other thermoplastics, PEI can be relatively expensive, which may limit its use in cost-sensitive applications.

2. Processing Difficulty: PEI has a high processing temperature and requires specialized equipment for molding and shaping. This can add to the overall manufacturing costs and complexity.

3. Brittleness: Despite its high strength and stiffness, PEI can be brittle at low temperatures, making it susceptible to impact and crack propagation in cold environments.

4. Limited Availability: Due to its specialized nature, PEI may not be as readily available as other thermoplastics, which could affect lead times and supply chain management.

In conclusion, PEI plastic material offers a unique set of advantages, including high temperature and chemical resistance, dimensional stability, and flame retardancy, making it a desirable choice for a wide range of demanding applications. However, its limitations, such as cost, processing difficulty, and brittleness, need to be carefully considered when evaluating its suitability for a specific use case. Overall, the versatility of PEI plastic material makes it an attractive option for industries that require high-performance thermoplastics.

Innovations and Developments in PEI Plastic Technology

Polyetherimide (PEI) is a high-performance engineering plastic that has seen significant innovations and developments in recent years. Its versatility and unique properties have made it an increasingly popular choice in various industries, and ongoing research and advancements continue to expand its capabilities. In this article, we will explore the versatility of PEI plastic material and discuss the latest innovations and developments in PEI plastic technology.

PEI is a thermoplastic with high heat resistance, excellent mechanical properties, and inherent flame retardancy. These characteristics make it an ideal material for demanding applications in industries such as aerospace, automotive, electronics, medical, and more. With a glass transition temperature of 217°C and a continuous use temperature of 170°C, PEI can withstand extreme temperatures without compromising its mechanical integrity.

One of the key innovations in PEI plastic technology is the development of reinforced PEI composites. By incorporating fillers such as glass fibers, carbon fibers, or mineral reinforcements, the mechanical and thermal properties of PEI can be further enhanced. These reinforced PEI composites offer improved strength, stiffness, and dimensional stability, making them suitable for even more demanding applications.

In addition to traditional injection molding, advancements in processing techniques have expanded the possibilities for PEI plastic material. For example, 3D printing with PEI has gained traction in recent years, allowing for the rapid prototyping and production of complex parts with high precision. This advancement has opened up new opportunities for designers and engineers to explore the full potential of PEI in additive manufacturing.

The chemical resistance of PEI is another area that has seen significant advancements. Innovations in polymer chemistry have led to the development of specialized grades of PEI that offer enhanced resistance to a wider range of chemicals, solvents, and fuels. This increased resistance expands the potential applications of PEI in industries where exposure to aggressive substances is a concern.

The ongoing research and development in PEI plastic technology also focus on improving its surface properties and aesthetics. New surface treatments and coatings have been developed to enhance the wear resistance, scratch resistance, and overall appearance of PEI components. These advancements have made PEI a more attractive option for applications where both performance and aesthetics are important.

Furthermore, the sustainability aspect of PEI plastic material is also a key focus of development. Efforts to improve the recyclability and biodegradability of PEI are ongoing, aligning with the growing emphasis on environmentally friendly materials in the industry.

In conclusion, the innovations and developments in PEI plastic technology have further enhanced the versatility and performance of this high-performance engineering plastic. From reinforced composites to advanced processing techniques and improved chemical resistance, PEI continues to evolve to meet the demands of diverse industries. As research and development efforts continue, we can expect to see even more exciting advancements in the capabilities of PEI plastic material in the future.

Future Prospects of PEI Plastic in the Market

PEI plastic, or polyetherimide, is a high-performance engineering plastic that offers a unique set of properties and benefits, making it a versatile and highly sought-after material in various industries. In this article, we will explore the future prospects of PEI plastic in the market, taking into consideration its properties, applications, and potential for growth.

Properties of PEI Plastic Material

PEI plastic is known for its exceptional thermal stability, high strength, and good chemical resistance. It can withstand high temperatures, making it suitable for applications where traditional plastics may fail. Additionally, PEI plastic exhibits excellent electrical properties, making it an ideal material for electronic and electrical components. Its inherent flame resistance and low smoke generation also make it a preferred choice for applications requiring high safety standards.

Applications of PEI Plastic Material

PEI plastic has found widespread use in various industries due to its unique combination of properties. In the medical field, it is utilized in the production of surgical instruments, medical device components, and sterilizable trays due to its biocompatibility and resistance to chemicals and steam sterilization. In the electronics industry, PEI plastic is used for connectors, sockets, and insulating components due to its excellent electrical performance. Moreover, it is also widely used in automotive, aerospace, and consumer goods industries for applications such as automotive sensors, aircraft interiors, and kitchenware.

Future Prospects in the Market

The future prospects of PEI plastic in the market are promising, driven by the growing demand for high-performance materials with exceptional properties. As industries continue to push the boundaries of performance and efficiency, the demand for PEI plastic is expected to rise, particularly in sectors such as healthcare, electronics, and transportation. With ongoing advancements in material technology, there is a growing focus on developing new grades of PEI plastic with enhanced properties, such as improved impact resistance and higher temperature capabilities, further broadening its application potential.

The adoption of PEI plastic material is also driven by its sustainability benefits. As environmental concerns and regulations continue to shape the industry landscape, the recyclability and low environmental impact of PEI plastic make it an attractive choice for manufacturers looking to reduce their carbon footprint and meet sustainability goals. With a strong emphasis on circular economy and resource efficiency, the demand for sustainable materials like PEI plastic is expected to grow in the coming years.

Furthermore, the ongoing research and development initiatives in the field of polymer science and engineering are paving the way for new opportunities for PEI plastic in emerging applications. As new formulations and processing techniques are being developed, the potential for PEI plastic to be used in novel applications, such as 3D printing, advanced composites, and additive manufacturing, is being explored, opening up new avenues for market growth.

In conclusion, the future prospects of PEI plastic in the market are bright, fueled by its exceptional properties, diverse applications, and sustainability benefits. With the continuous advancements in material technology and the evolving needs of various industries, PEI plastic is poised to play a significant role in shaping the future of engineering plastics. As the market continues to embrace high-performance and sustainable materials, PEI plastic is well-positioned to thrive and expand its presence in the global market.

Conclusion

In conclusion, the versatility of PEI plastic material is truly remarkable. From its high temperature resistance to its excellent mechanical properties, PEI has proven itself to be a valuable material in a wide range of industries. Whether it's used in medical devices, aerospace components, electrical insulation, or any other application, PEI offers a unique combination of properties that make it a standout choice. As new advancements continue to be made in the field of polymer chemistry, it's likely that we'll continue to see even more innovative uses for PEI in the future. Its versatility makes it an invaluable material for engineers and designers looking to create high-performance products, and its potential for further development is an exciting prospect. PEI's potential is truly boundless, and it will be exciting to see how this material continues to shape our world in the years to come.